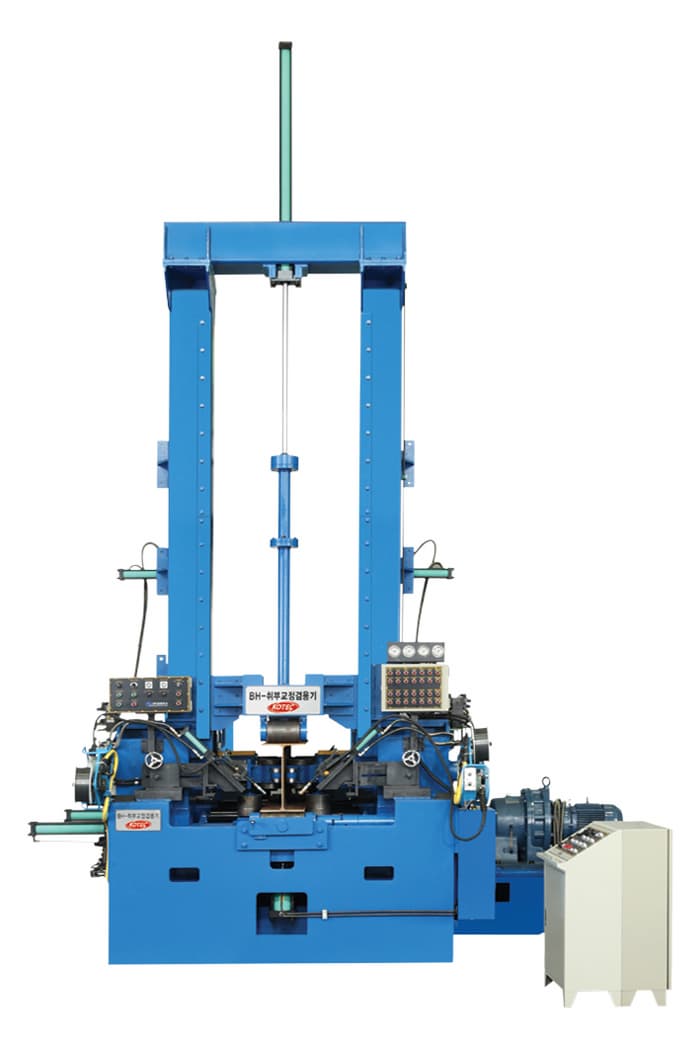

Assembling and straightening machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- KOTEC

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- straightening machine, assembling and straightening machine, assembling machine, b-h assembling and straightening machine

- Category

- Machinery & Parts

KOTEC Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | Assembling and straightening machine | Certification | - |

|---|---|---|---|

| Category | Machinery & Parts | Ingredients | - |

| Keyword | straightening machine , assembling and straightening machine , assembling machine , b-h assembling and straightening machine | Unit Size | - |

| Brand name | KOTEC | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

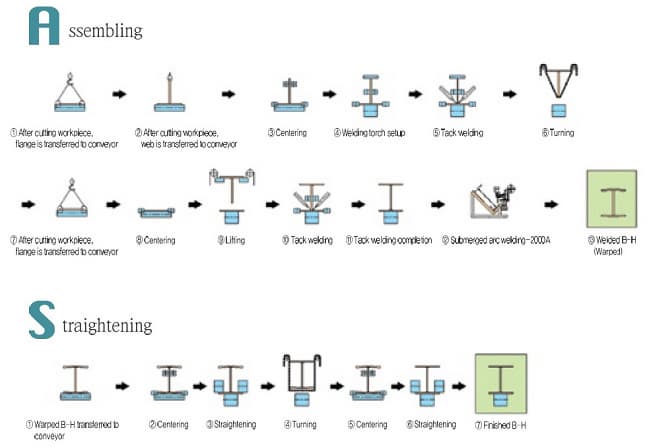

Integrated system for double purpose - assembling & straightening

Features

Designed for durability

This equipment is our fruitful outcome from long experience in the structural steel industry. Main components are specially selected and combined to have high rigidity in order to maintain its permanent accuracy in spite of applications of long standing.

Suitable for small quantity production

Based on 10 working hours a day, this combined equipment is suitable for small quantity production less than 500 ton per month.

Reduced manpower required

Only 1 operator is required to handle this machine because of convenient operation system.

Space-saving & Cost-effective

This combined machine for assembling & straightening saves space and investment cost and is suitable for limited workshop with short length and narrow width.

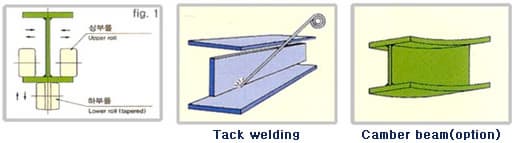

Camber beam

Based on workpiece length 10m, the cambering below 30mm is covered by standard KTA-6080 and KTAS-6080, pressing flange and web. Flange straightening is completed by 1 time ~ 4 times rolling in accordance with workpiece quality and flange thickness.

Specification

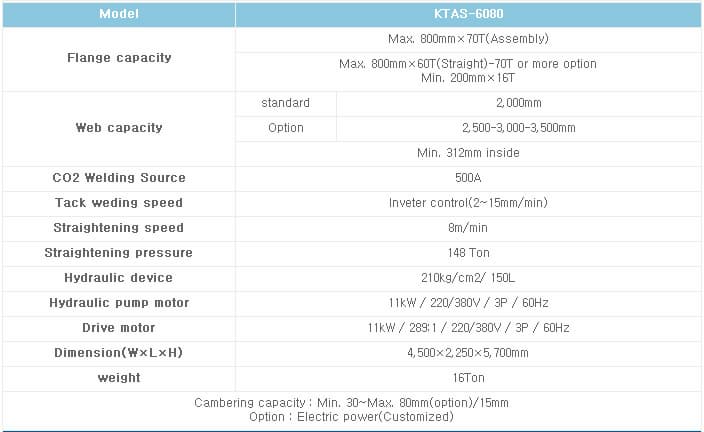

| Model | KTAS-6080 | |

| Flange capacity | Max. 800mm×70T(Assembly) | |

| Max. 800mm×60T(Straight)-70T or more option Min. 200mm×16T |

||

| Web capacity | standard | 2,000mm |

| Option | 2,500-3,000-3,500mm | |

| Min. 312mm inside | ||

| CO2 Welding Source | 500A | |

| Tack weding speed | Inveter control(2~15mm/min) | |

| Straightening speed | 8m/min | |

| Straightening pressure | 148 Ton | |

| Hydraulic device | 210kg/cm2/ 150L | |

| Hydraulic pump motor | 11kW / 220/380V / 3P / 60Hz | |

| Drive motor | 11kW / 289:1 / 220/380V / 3P / 60Hz | |

| Dimension(W×L×H) | 4,500×2,250×5,700mm | |

| weight | 16Ton | |

| Cambering capacity : Min. 30~Max. 80mm(option)/15mm Option : Electric power(Customized) |

||

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Kim, Woo Sung

- Address

- 785-203. Seokpo-ri, Jangahn-myon,, Hwaseong-si,Gyeonggi-do,

- Product Category

- Machinery & Parts,Metal & Metallurgy Machinery,Other Metal & Metallurgy Machinery

- No. of Total Employees

- 501-1000

- Company introduction

-

Thank you so much for visiting KumKwang Tech Co., Ltd. We,Kumkwang Tech,which has being grown with the local structural steel industry are endeavoring to approach closer to customers with the first alms and intentions all the time,being never content withe the largest sales accomlishment in the local market. Based on the versed englneering service team acknowledged by a variety of manufacturers in connection with Japanese strucural steel machines and know-how freom ling experience,we are giving all customers the total solutions from design to manufacture,installaion and maintenance service in order to create the maximum productivity with the minimum investment costs. All of we are doing our urmost to satisty customer's productivity increase and the higest quallty requirements and contrilbute to development of the structural steel industry We would like to extend our deep grtitude for all customers cherishing KumKwang Tech and ask you of continuous interest and encouragement.

- Main Markets

-

Australia

Australia

Iran

Iran

Japan

Japan

Malaysia

Malaysia

Saudi Arabia

Saudi Arabia

Singapore

Singapore

South Korea

South Korea

U.S.A

U.S.A

Viet Nam

Viet Nam

- Factory Information

-

1st Factory of Kumkwang Tech Co.,Ltd,

2nd Factory of Kumkwang Tech Co.,Ltd,

3rd Factory of Kumkwang Tech Co.,Ltd,

China Factory of Kumkwang Tech Co.,Ltd

- Main Product

Related Products

_2.jpg)

Turbowin Turbo Blower (WL Series)

MECHANICAL PACKING, GLAND PACKING, YARN ROPE PACKING

AIS3000 HD

Airless Pump (Ratio 63:1 Airless Pump)

_2.jpg)

Micro Probe System (MPS-PTH)